|

Dept. of Measurement and Information Systems, Budapest University of Technology and Economics Digital Signal Processing Laboratory

|

|

DRD - Dynamic Railway Diagnostic System

The system is designed to measure the weight of railway carriages moving at their normal traveling speed (dynamic measurement). The system consists of multiple DSP-based measurement modules and a HOST PC. The sensors of the system are strain gages, which measure the deformation of the rail caused by a passing train. The modules are placed next to the sensors, directly on the rails.

Dynamic Weight Measurement

The in-motion weighing of railway carriages is a widely used and accepted method. The commercially available systems are typically performing accurately and reliably below 25 km/h, so the trains have to slow down before the measurement section. Besides the loss of time, this can lead to the slipping of the freight ahead or sideways, which increases the possibility of accidents. That explains why static measurement systems can only be used limitedly to monitor railway traffic.

In case of dynamic measurement, the train passes over the measurement section without slowing down, so the weight of the individual wheels and the weight distribution can be examined in normal travelling conditions.

The Measurement System

The system consists of a HOST PC and multiple measurement modules. The modules and the PC are connected through an RS-485 industrial serial line. The modules are placed directly on the rail, close to the strain gage sensors, in order to minimize the length of the signal wire between the sensor and the module to maximizing the signal to noise ratio.

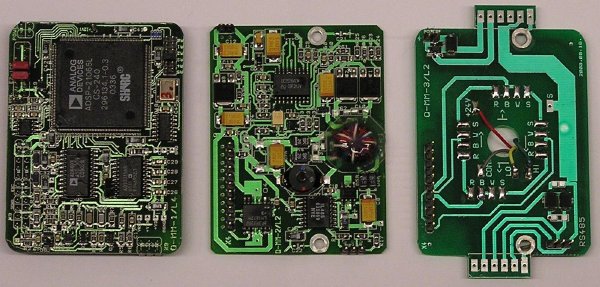

Fig. 1. Measurement modules

Measurement Modules

The modules' central component is the Analog Devices ADSP-21065L digital signal processor. This processes the sampled signal of the strain gage sensors, i. e. it calculates the weight of each wheel and produces the compressed version of the deformation signal. After the online measurement, all these data are sent to the PC for post-processing.

Fig. 2. Panels of the module

Fig. 3. The mounted measurement module

Diagnostics

Besides the weight information, the system is capable of providing additional information about the railway carriages. The visualization of the weight distribution on the wheels can reveal problems such as unevenly distributed freight or swinging motion of the train. The latter effect can be observed in case of fast moving trains, the weight is displaced periodically over the measurement section, due to a slight swinging movement.

Another important diagnostic function is the faulty wheel detection. The wheels of the train can deform due to intense braking, which are not rolling perfectly afterwards. The detection of such wheels is very important, as they are constantly "hitting" the rails and damaging it seriously. Such wheels can be detected based on the shape of the deformation signal, measured by the strain gages.

Related Publication:

Further information: Károly Molnár

|